Terawell is a services company dedicated to providing state of the art solutions that are safe, reliable, and produce unmatched results, ensuring smooth operations for our Clients.

Terawell Oilfield Services is a services company dedicated to providing state of the art solutions for Oil & Gas producers.

We at Terawell Oilfield Services believe passionately in our core values – to relentlessly drive excellence in quality; to deliver our commitments to our clients; to genuinely collaborate as teams internally and externally, but above all, to only conduct our business ethically and with absolute integrity, not just because it is a must to comply, but first and foremost because it is our deepest value.

Our clients benefit from our unrivalled understanding of their challenges and unique environmental, geological and cultural conditions that exist within our home markets. By merging our invaluable local experience with a highly skilled and motivated team, the latest technologies and quality-driven processes, we are aiming to establish a reputation for delivering customized and competitive solutions regardless of the conditions.

Uncompromising business ethics and professional integrity form the foundations from which Terawell Oilfield Services is built. This permeates into everything we do, including how we approach the identification of solutions to meet our clients’ requirements. By taking the role of trusted business partner as opposed to a mere supplier, we go to great lengths to leverage our deep internal expertise. We do not believe in a ‘one size fits all’ service offering and the inefficient excess of work this can lead to. We aim to differentiate ourselves by consistently providing greater value to our clients through intelligent and cost effective solutions that are tailored to their needs, and delivered with our relentless approach to excellence and expert knowledge of our markets.

We take pride in investing in our employees and services that help our customers achieve their goals.

Quality, health, safety, and the environment are key priorities for Terawell Oilfield Services.

We aspire to achieve the highest quality and HSE standards with a commitment to support our customers in providing a safe environment for their employees.

“We are proud of our past and passionate about our future and look forward to continuing our success alongside each of our Clients & partners.”

To be the recognized leader in Oilfield Services in the Region

To establish Terawell Oilfield Services as the preferred choice of clients, known for our quality, adaptability and flexibility for meeting their f ield service needs

Oilfield & Industrial Waste Management Solutions

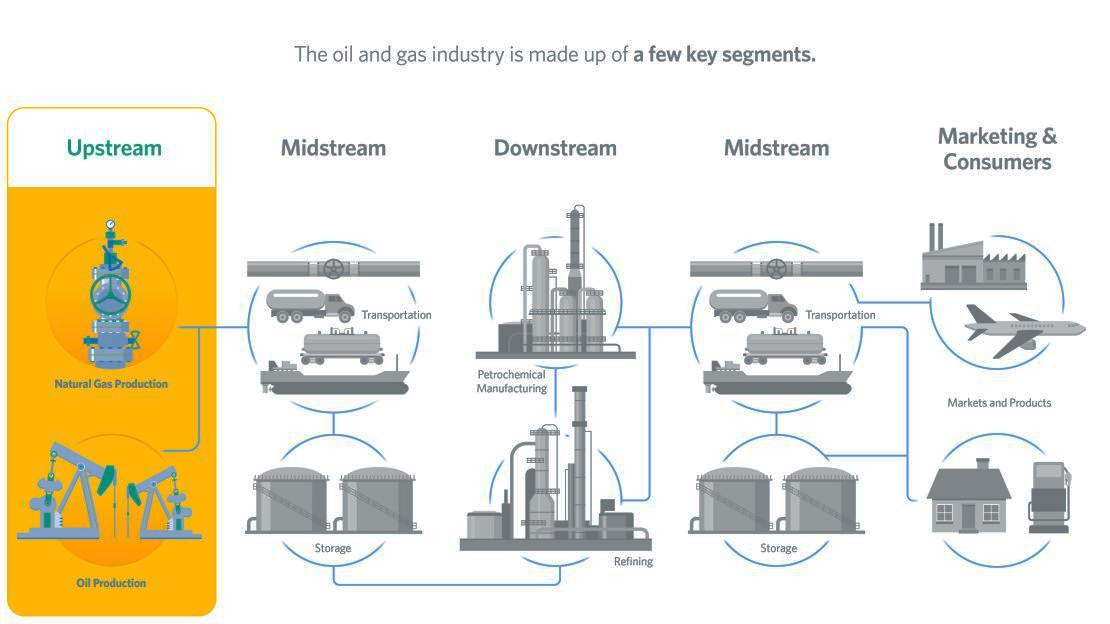

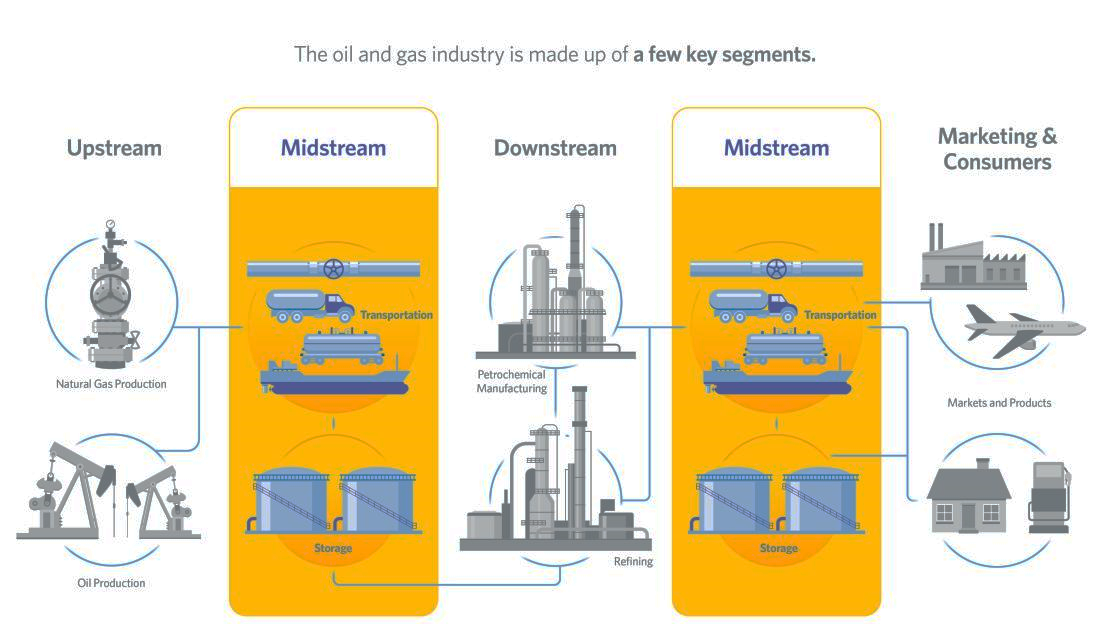

Our company is a leading provider of waste management solutions, specializing in the collection, treatment, and disposal of industrial and oilfield waste. With extensive experience in the oil & gas sector, we deliver safe, compliant, and environmentally responsible services tailored to the unique operational needs of upstream, midstream, and downstream operations.

We are fully registered with the relevant regulatory authorities in Yemen, ensuring all our services meet local legal requirements and environmental standards.

Our expertise covers hazardous and non-hazardous waste handling, chemical and oil waste treatment, drilling mud and sludge management, produced water treatment, recycling, and disposal services.

By combining technical expertise, specialized equipment, and industry best practices, we ensure minimal environmental impact, enhanced operational safety, and regulatory compliance. Our integrated solutions enable oilfield operators to manage waste efficiently, reduce environmental footprint, and maintain sustainable operations.

“Turning Industrial Waste into Safe, Efficient, and Environmentally Responsible Solutions”

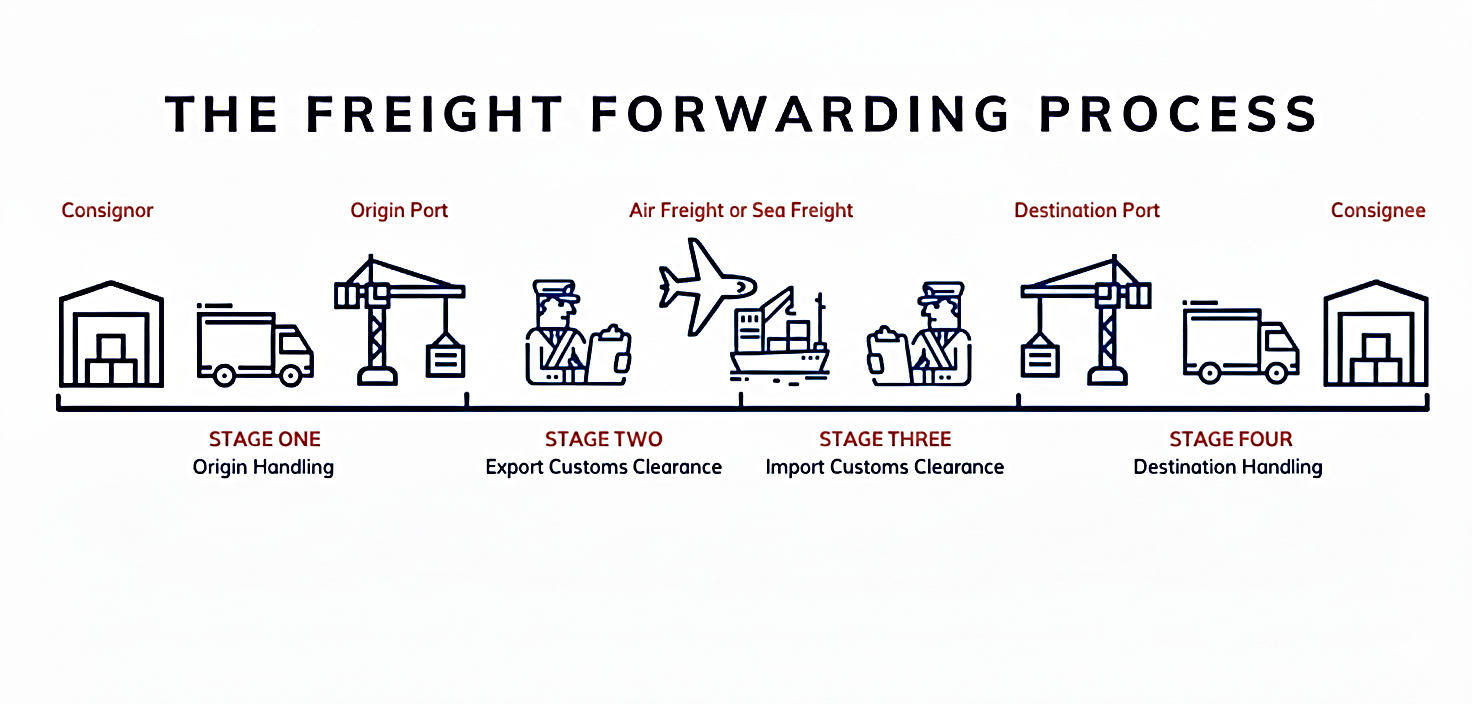

At Terawell we provide comprehensive freight forwarding and customs clearance solutions supporting the oil & gas, industrial, and infrastructure sectors across Yemen.

Our services ensure the efficient, compliant, and timely movement of equipment, materials, chemicals, and project cargo through air, sea, and land routes.

We manage the complete logistics cycle — including international shipping coordination, port handling, documentation, customs brokerage, and final delivery — while ensuring full compliance with Yemeni customs laws and trade regulations.

Safety is embedded in every operation. Our logistics processes follow strict Health, Safety & Environment (HSE) standards, with trained personnel, risk assessments, secure cargo handling, and emergency preparedness to protect people, assets, and the environment.

With a strong focus on regulatory compliance, operational transparency, and on-time delivery, we enable seamless import and export operations for critical oilfield and industrial projects.

“Compliant clearance. Safe logistics. On-time delivery across Yemen.”

At Terawell we deliver safe, reliable, and fully integrated trucking and logistics solutions for the oil & gas industry across Yemen and cross-border operations.

We support drilling sites, production facilities, pipelines, and processing plants with the secure transportation of equipment, tubulars, chemicals, heavy machinery, and personnel — even in remote and high-risk environments.

Our operations are executed under strict Health, Safety & Environment (HSE) management systems, aligned oilfield best practices. We ensure trained drivers, certified equipment, route risk assessments, emergency response readiness, and continuous safety monitoring across all transport activities.

For international movements, we provide full cross-border logistics coordination, including customs clearance, duty handling, and compliance with regional trade and transport regulations — ensuring fast, transparent, and disruption-free delivery.

With a focus on zero incidents, regulatory compliance, and on-time performance, we deliver logistics solutions that keep oilfield operations moving safely and efficiently.

“Safe transport. Compliant logistics. Oilfield performance — across borders.”

We are a leading provider of skilled manpower and consultancy services for Yemen’s oil & gas sector, with experienced personnel and technical expertise, fully compliant with industry standards and local regulations.

Terawell is a leading provider of specialized manpower and consultancy services for the oil & gas industry in Yemen, supporting upstream, midstream, and downstream operations. We offer highly skilled personnel and technical expertise across a wide range of services, including oilfield operations, seismic surveys, plant operations e.t.c

Our team is comprised of experienced engineers, technical specialists, and field professionals, trained to meet the strict operational, safety, and regulatory standards of the oil and gas sector. We are fully compliant with local labor regulations and industry standards, ensuring that all personnel and services are delivered safely, efficiently, and professionally.

Key Services:

- ↗ Oilfield Operations Support: Drilling, production, and wellsite operations

- ↗ Seismic & Survey Operations: Field crew, geotechnical and geophysical support

- ↗ Commissioning & Start-up Services: Equipment installation, testing, and system integration

- ↗ Plant Operations Support: Process control, mechanical, electrical, and instrumentation expertise

- ↗ Health, Safety, and Environmental Compliance: On-site HSE monitoring, risk assessment, and regulatory compliance

Why Choose Us?

Expertise: Our team consists of experienced professionals with a deep understanding of industry trends and workforce dynamics.

Quality: We are committed to delivering high-quality candidates who meet your precise needs.

Flexibility: Our services are designed to be adaptable, ensuring that we can quickly respond to your changing requirements.

Reliability: We pride ourselves on being a dependable partner, dedicated to supporting your business with integrity and excellence.

At Terawell we provide comprehensive Safety Training and Certification programs tailored to the demanding requirements of the oil & gas, industrial, and infrastructure sectors across Yemen. Our training solutions are designed to build a strong safety culture, ensure regulatory compliance, and enhance workforce competency in high-risk operational environments.

We deliver both classroom and on-site practical training covering critical areas such as HSE induction, hazard identification, permit-to-work systems, working at height, confined space entry, lifting operations, fire fighting, emergency response, defensive driving, and contractor safety management.

All programs are aligned with recognized international standards and best practices, including ISO 45001, OSHA guidelines, API safety principles, and industry-approved certification frameworks, ensuring personnel meet oilfield and industrial compliance requirements.

With experienced instructors, modern training methodologies, and competency-based assessments, we certify personnel to operate safely, efficiently, and in full compliance with project HSE policies and regulatory obligations.

Our mission is to reduce incidents, protect people and assets, and support clients in achieving Zero Harm operations.

“Building competence. Driving compliance. Creating safer operations.”

At Terawell, we deliver reliable, fully maintained light vehicle rental and leasing solutions designed specifically for oilfield and industrial operations across Yemen.

Our fleet supports drilling sites, seismic crews, production facilities, and project operations with dependable, field-ready transportation in remote and demanding environments.

Vehicle safety is a core priority. All units are maintained under strict HSE vehicle management systems, including preventive maintenance schedules, daily inspections, safety equipment installation, and compliance with oilfield driving standards.

We implement comprehensive driver management and training programs, covering defensive driving, fatigue management, journey risk assessments, emergency response, and site-specific HSE requirements — ensuring safe operations at all times.

Our cross-project fleet support model allows rapid mobilization, replacement units, and centralized maintenance coverage across multiple oilfield locations, minimizing downtime and ensuring operational continuity.

With a strong commitment to safety, reliability, and operational efficiency, we provide transportation solutions that keep oilfield operations moving without compromise.

“Safe vehicles. Trained drivers. Reliable oilfield mobility across Yemen.”

“We are Yemen’s trusted provider of lifting and earthwork equipment, powering oilfield projects with safe, reliable, and high-performance machinery.”

Terawell is a leading provider of lifting and earthwork equipment in Yemen, supporting oilfield, pipeline, plant, and infrastructure projects across the energy sector.

We supply reliable, heavy-duty machinery and lifting solutions designed to meet the demanding conditions of oil & gas operations, ensuring safety, efficiency, and operational excellence.

With extensive local experience and a strong understanding of oilfield requirements, we deliver cranes, forklifts, excavators, loaders, heavy transport equipment, Water Trucks and specialized lifting systems, backed by professional support and strict safety compliance.

Our solutions enable operators to execute construction, maintenance, and heavy handling activities with confidence and precision.

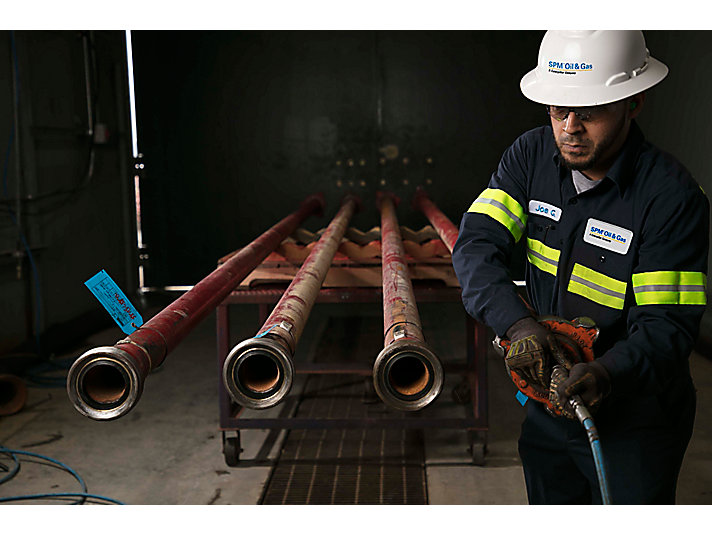

At Terawell we provide comprehensive inspection, testing, and certification services for oilfield equipment and tubulars, ensuring operational integrity, safety, and compliance with international standards. Our services support the oil & gas sector in maintaining high-performance equipment, extending asset life, and preventing operational risks.

Our Capabilities Include:

- ↗ Tubular & Pipe Inspection: Non-destructive testing (NDT), dimensional checks, and visual inspection for drill pipes, HP iron, casings, and production tubing.

- ↗ Equipment Certification: Verification, certification, and traceability of valves, pressure vessels, lifting equipment, and other critical assets.

- ↗ Compliance Assurance: Alignment with API, ISO, ASME, NACE, and other industry standards for quality and safety.

- ↗ Testing Services: Ultrasonic testing (UT), magnetic particle testing (MPT), radiography (RT), hardness testing, and more.

- ↗ Reporting & Documentation: Detailed inspection reports, certificates of compliance, and maintenance recommendations.

Why Choose Us:

We combine technical expertise, certified inspectors, and advanced inspection technology to deliver reliable, accurate, and timely services, ensuring your equipment meets operational and regulatory requirements.

“Integrity, safety, and compliance — certified at every step.”

General Oilfield Services

At Terawell, we provide comprehensive oilfield services tailored to support upstream, midstream, and downstream operations in the oil & gas industry. With extensive experience across drilling, production, maintenance, and plant operations, we deliver safe, efficient, and reliable solutions that meet the highest industry standards.

Our Services Include:

- ↗ Drilling and well services

- ↗ Production support and maintenance

- ↗ Cementing and stimulation operations

- ↗ Equipment supply, installation, and commissioning

- ↗ Pipeline and plant operations support

- ↗ Technical manpower and consulting services

Why Choose Us:

Our team of skilled professionals, backed by certified processes and compliance with API, ISO, ASME, and OSHA standards, ensures projects are executed safely, on schedule, and to the highest quality.

“Delivering safe, reliable, and efficient solutions across the oilfield lifecycle.”

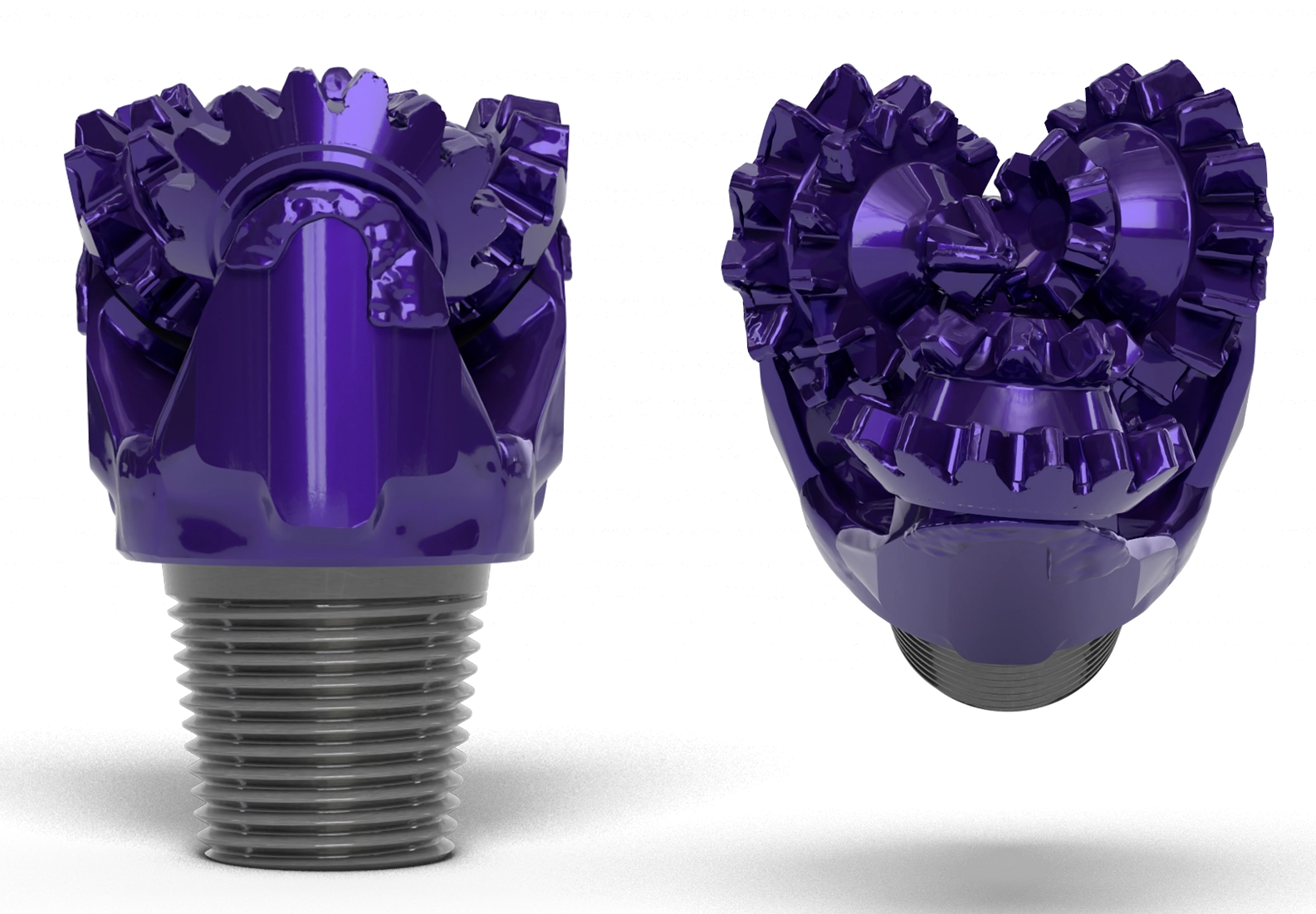

Drill Bits & Drilling Solutions

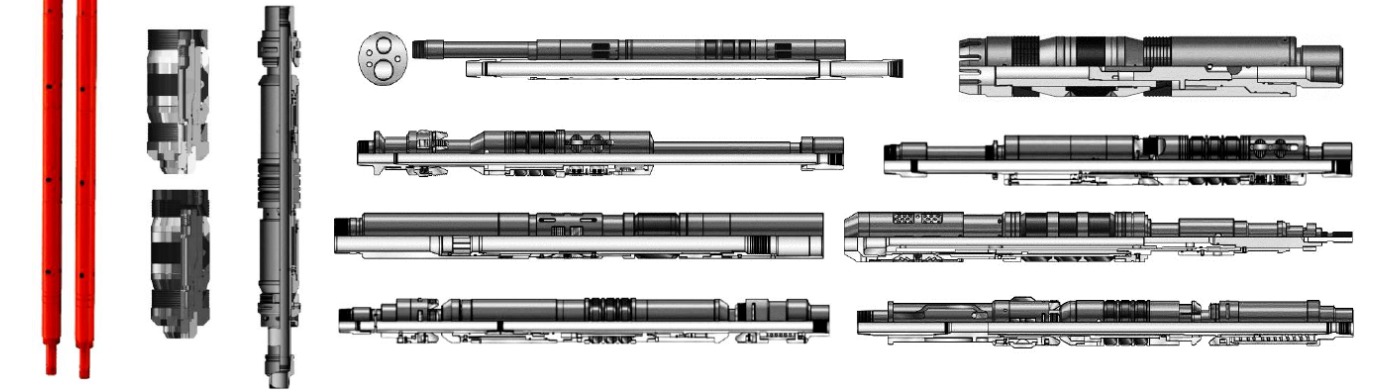

Well Construction

Completion & Downhole

Varel's Drill Bits designed to deliver a better drilled wellbore. Varel Drill Bits concentrate on solving problems specific to the application. Whether it is drilling through transitions requiring durability and control, or building angle requiring responsiveness and consistency, or holding direction in an extended reach lateral requiring speed and reliability, Varel Drill Bits offer bit technology that is perfectly designed for delivering these necessities.

Terawells are the exclusive representative for Varel Energy Solutions (Varel Drill Bits) in the Republic of Yemen.

PDC Drill Bits

- • Standard

- • Specialized

- • Completions

- • Attributes

- • Integrated Solutions

↗ Varel Energy Solutions' system approach to delivering a better drilled wellbore.

↗ Varel's flagship PDC plug mill engineered to cut through the chaos of frac plug drill outs

↗ High impact PDC features designed to optimize performance and value

↗ A complete suite of proprietary softwares, enabling the development of the most optimized PDC drill bit design.

Roller Cone Drill Bits

• Standard

↗ Industry's leading hybrid roller cone, designed for milling applications across various downhole environments.

↗ A dedicated roller bearing product line for large diameter drilling (14" - 45")

↗ Tungsten Carbide Insert or Steel Teeth sealed journal bearing bits for higher energy applications with increased rotary speeds, increased weight on bit, or both.

↗ Slimhole series of Tungsten Carbide Insert and Steel Teeth sealed journal bearing products designed for straight hole or directional drilling on stick pipe, motors, or coiled tubing applications.

↗ A dedicated product line for underbalanced drilling with air, water mist, and/or foam fluid systems.

↗ Specifically designed to target non-homogeneous downhole components.

• Workover

↗ Industry leading steel teeth roller cone bits for re-entry and remedial operations.

Primary Cementing Equipment

With a focus on reliability and operational excellence, we help operators achieve more efficient and productive completions.

- • Bowspring Centralizers

- • Solid Body Centralizers

- • Cement Basket

- • Stop Collars

- • Float Equipment

- • Integrated Shoe Track

- • Cementing Head

- • Latch-in Top Plug

- • Latch-in Rupture Plug

- • Cement Retainer

- • Cement Stage Tool

- • Cement Plug

↗ Complete offering of bow spring centralizers to help get casing, liners, or screens to bottom with ease in demanding applications.

↗ Wide selection of cementing products and tubular accessories to support well completions/production.

↗ Differentiated full range of float equipment and cementing tools used in running casing, liner, or screen applications.

↗ A proprietary wet shoe track designed to maximize performance predictability and minimize operational costs.

↗ A Complete offering of solid body centralizers to help get casing, liners, or screens to bottom with ease in demanding applications.

↗ A complete range of stop collar options to suit any centralizer application.

Casing Deployment

Our solutions enhance milling efficiency, support effective isolation drill-outs, and provide valuable insights into completion performance.

• Casing Drilling

Float & Reamer Shoe Noses

• Casing Shoes

LRL PILOT GUIDE SHOE

FTR PILOT GUIDE SHOE

PILOT GUIDE SHOE

• Reamer Shoes

PREDOTOR™

REAPER®

PENOTRATOR®

↗ Combines industry recognized PDC drill bit technologies, force balancing, cutting structure wear modeling, and computational fluid analysis with flexible manufacturing technology.

↗ Guide shoe technology to aid with the running of any casing, liner, and screen applications.

↗ A unique set of casing drilling technologies to enable effective milling and torque reduction requirements.

↗ Varel's Well Construction solutions are widely recognized for their ingenuity, performance, and reliability.

UPPER COMPLETIONS PRODUCTS

- • Wireline Entry Guide

- • Landing Nipple

- • Expansion Joint

- • Self Aligning Mule Shoe

- • Millout Extension

- • Bull Nose

- • Seal Bore Extension

- • Seal Unit & Seal Unit Extension

- • Adapter/Cross-over

- • Pump Out Plug

- • Blast Joint

- • Perforated Pup Joint

- • Pup Joint

- • Flow Coupling

- • Polished Bore Receptacle

PACKERS SYSTEM

- • Hydraulic Set Retrievable Packers

- • Mechanical Set Retrievable Packer

- • Service Packer

- • Hydraulic Set Retrievable Sealbore Packers

- • Wireline Set Retrievable Sealbore Packers

- • Hydraulic Set Permanent Sealbore Packers

- • Wireline Set Permanent Sealbore Packers

- • Accessories For Permanent Sealbore Packers

(Hydraulic Setting Tool, Wireline Adapter Kit, Anchor Tubing Seal Assembly, Locator Tubing Seal Assembly, Seal Bore Extension, Self Orienting Mule Shoe, Packer Milling Tool)

BRIDGE PLUG & CEMENT RETAINER SYSTEM

- • Permanent / Millable Bridge Plug & Cement Retainer

- • Retrievable Bridge Plug

- • Accessories For Bridge Plug & Cement Retainer

(Snap Latch Setting Tool, Snap Latch Stinger Sub & Control, Mechanical Setting Tool, Wireline Adapter Kit)

FLOW CONTROL SYSTEM

- • Landing Nipple / Seating

- • Lock Mandrel / Blanking Plug

- • Running & Pulling Tools

- • Sliding Sleeve And Accessories

(Model "Sl" Elastomeric Sliding Sleeve Model "Smd" & "Smu" Non-elastomeric Sliding Sleeve, Model "Sd" Shifting Tool, Model "Sm" Shifting Tool)

Sledgehammer Leads the way in offshore and onshore cementing and float apparatus, and our hallmark is quality and unrivalled expertise in our field.

Sledgehammer is a leading API & ISO 14001, 18001, 9001 certified manufacturer of cementing equipment. Our products include Centralizers; Stop Collars; Reamer Shoes; Float Shoes; Float Collars; Stage Cementing Tools; Bridge Plugs and Cement Retainers.

We enjoy the unrivalled reputation of being the largest producer and supplier of offshore and onshore cementing and float apparatus across Asia and pride ourselves as the leading reliable source of original and quality equipment.

DOWNHOLE PRODUCTS

A VAREL ELITE BRAND

Drilling, Cementing & Production Chemicals

Our company provides a comprehensive range of specialty chemicals and additives engineered for upstream oil & gas operations, including drilling, completion, production, and cementing applications. Our solutions are designed to optimize well performance, enhance operational efficiency, and ensure compliance with international standards in challenging upstream environments. We supply high-performance oilfield chemicals tailored for drilling muds, cementing, well stimulation, and production fluids, ensuring equipment protection, formation integrity, and operational safety under extreme conditions.

Key Chemicals & Additives for Upstream Operations:

Drilling Fluids / Mud Additives:

- ↗ Bentonite / Clays

- ↗ Barite / Weighting Agents

- ↗ PAC / PAC-L / PAC-R Polymers

- ↗ Xanthan Gum, Guar Gum, and other viscosifiers

- ↗ Lignosulfonates and Derivatives (Fluid Loss Control)

- ↗ Starch & Modified Starches

- ↗ Defoamers / Anti-foam Agents

- ↗ Shale Inhibitors (KCl, Glycol-based, Polyamines)

- ↗ Biocides & Bactericides (for mud & water systems)

- ↗ Lubricants & Friction Reducers (Drill String & Tubing)

- ↗ pH & Alkalinity Modifiers

- ↗ Surfactants & Emulsifiers for Oil-based Muds

Cementing Additives:

- ↗ Retarders (Class G & H Cement)

- ↗ Accelerators (for cold and deep wells)

- ↗ Fluid Loss Control Additives

- ↗ Dispersants & Plasticizers

- ↗ Lost Circulation Materials (LCMs)

- ↗ Extenders (Barites, Clays, Silica)

- ↗ Specialty Slurries for HPHT wells

Workover & Well Maintenance Chemicals:

- ↗ Clay Stabilizers

- ↗ Lost Circulation Materials

- ↗ Well Cleaners & Solvents

- ↗ Cement Removers

- ↗ Scale & Deposit Removers

Production & Completion Chemicals:

- ↗ Corrosion Inhibitors (for tubing, casing, and flowlines)

- ↗ Scale Inhibitors (preventing CaCO3, BaSO4, SrSO4 deposits)

- ↗ Paraffin / Asphaltene Dispersants

- ↗ Demulsifiers (water-oil separation)

- ↗ H2S / CO2 Scavengers

- ↗ Biocides & Microbial Control Agents

- ↗ Foamers & Defomers (for production handling)

- ↗ Well Stimulation Chemicals (Acids, Gels, Breakers)

- ↗ Surfactants for Enhanced Oil Recovery (EOR)

All chemicals are designed for high-performance in extreme temperatures, high pressures, and corrosive environments, with compliance to API, ASTM, ISO, NACE, and OSHA standards. We also provide technical support, application guidance, and on-site assistance, ensuring chemicals are optimized for specific well conditions, drilling programs, and production challenges.

By combining premium-quality upstream chemicals, engineering expertise, and global compliance, we help operators maximize well efficiency, maintain equipment integrity, and achieve safe, cost-effective drilling, cementing, and production operations.

Pipeline & Processing Plant Chemicals & Waste Management

Teawells is a leading provider of specialized chemicals solutions for midstream oil & gas operations, including pipelines, pumping stations, and processing plants. We deliver safe, compliant, and efficient solutions designed to optimize pipeline integrity, enhance processing efficiency, and manage industrial waste responsibly.

We are fully registered with the relevant regulatory authorities in Yemen, ensuring that all our operations meet local and international environmental, health, and safety standards. With extensive experience in the midstream sector, we support operators with chemical solutions, process optimization, tailored for crude oil, natural gas, and hydrocarbon processing systems.

Pipeline Flow Assurance & Protection Chemicals:

- ↗ Corrosion Inhibitors (internal pipeline and tank protection)

- ↗ Scale Inhibitors (CaCO3, BaSO4, SrSO4)

- ↗ Paraffin & Asphaltene Dispersants

- ↗ Demulsifiers & Emulsion Breakers

- ↗ Biocides & Microbial Control Agents

- ↗ H2S & CO2 Scavengers

- ↗ Foamers & Defoamers

- ↗ Drag/Friction Reducers / Flow Improvers

Pipeline Flow Assurance & Protection Chemicals:

- ↗ Cooling Water Treatment Chemicals

- ↗ Boiler Water Treatment Chemicals

- ↗ Anti-Scaling & Anti-Fouling Additives

- ↗ Solvents & Degreasers for Equipment Maintenance

- ↗ Chemical Dosing Systems for Process Optimization

- ↗ Gas Dehydration & Treatment Chemicals

- ↗ Demulsifiers for Oil/Water Separation

- ↗ Specialty Additives for Hydrocarbon Separation & Stabilization

All chemicals and services are designed for high-performance under extreme operating conditions, ensuring equipment protection, regulatory compliance, and operational efficiency. Our solutions comply with API, ASTM, ISO, NACE, and OSHA standards, providing operators with safe, sustainable, and reliable midstream operations..

By combining technical expertise, registered waste management services, and high-performance chemicals, we help midstream operators maximize pipeline integrity, optimize processing efficiency, and maintain environmental and operational compliance..

HFO/Diesel & Refinery Chemicals Solutions

Our company delivers a complete range of specialty and process chemicals for the oil & gas downstream, HFO/Diesel, and refinery sectors, designed to optimize operational efficiency, enhance equipment performance, and ensure compliance with industrial and environmental standards.

We supply refinery-grade chemicals specifically formulated for HFO, Diesel, and other refined hydrocarbon streams. These chemicals are engineered for high performance under extreme conditions, ensuring equipment reliability, reduced fouling, and extended service life.

Key Chemicals & Additives Include:

- ↗ Corrosion Inhibitors - for storage tanks, pipelines, and refinery equipment

- ↗ Scale & Deposit Control Agents - anti-scaling and fouling prevention

- ↗ Demulsifiers / Emulsion Breakers - for water-oil separation

- ↗ Water Treatment Chemicals - including boiler treatment, cooling water treatment, and blowdown chemicals

- ↗ Biocides & Microbial Control Agents - to prevent microbial contamination and H2S generation

- ↗ pH & Alkalinity Regulators - maintaining optimum process conditions

- ↗ Fuel Additives - including pour point depressants, viscosity modifiers, cetane improvers, and anti-oxidants

- ↗ Lubricants & Anti-Wear Additives - for pumps, compressors, and moving equipment

- ↗ Antifoaming / Defoaming Agents - for process and wastewater systems

- ↗ Desalting Chemicals - for crude oil pre-treatment

- ↗ Demetallization & Dewaxing Chemicals - for refining process optimization

- ↗ Sludge & Deposit Dispersants - for tanks and equipment cleaning

- ↗ Hydrotreating / Hydroprocessing Additives - for improved fuel quality and refining efficiency

- ↗ Chemical Injection & Dosing Systems - including sampling and metering solutions

Our solutions are backed by technical application expertise, including chemical selection, dosing strategies, and process optimization to meet the unique requirements of refineries, fuel terminals, and HFO/Diesel handling operations. All products are compliant with international standards including ASTM, ISO, REACH, and OSHA, ensuring safe handling, environmental compliance, and consistent performance. By combining industry-grade chemicals, engineering support, and regulatory compliance, we help clients maximize throughput, maintain equipment integrity, and achieve reliable, cost-effective downstream operations..

Oilfield Equipment & Pipeline Solution

Our company delivers comprehensive oil & gas equipment, valves, and pipeline accessories for upstream, midstream, and downstream operations. We specialize in engineered solutions for hydrocarbon, LNG, LPG, steam, water, and process systems, combining high-quality products with technical expertise to ensure operational reliability, safety, and compliance with international standards.

Valves & Control Systems:

We provide a complete portfolio of industrial valves, including gate, globe, check, ball, butterfly, control, instrumentation, axial control, and HIPPS/axial isolation valves, designed for isolation, throttling, process control, and safety applications. Valves are available in sizes ½" to 120", pressure ratings 150CL to 4500CL, and in materials ranging from carbon steel to super duplex stainless steel, nickel alloys, and titanium. Features include wedge and parallel slide designs, pressure seal bonnets, extended bonnets for cryogenic applications, motorized actuation, and multi-end connections (flanged, butt-weld, threaded, socket weld). All valves comply with API (600, 602, 603, 6A), ANSI, ASME, ISO, and NACE standards.

Pipeline Products & Accessories:

Our supply includes pipes, fittings, flanges, gaskets, studs and bolts, branch fittings, thermowells, isolation kits, expansion joints, strainers, filters, flame arresters, and chemical injection/sampling systems, all engineered to meet stringent operational and environmental requirements. We provide high-pressure and severe-service equipment, including heat exchangers, pressure vessels, reactors, and specialized urea and ammonia process equipment for onshore and offshore applications.

Through a combination of premium-quality products, engineered solutions, and global compliance, we deliver reliable, durable, and cost-effective equipment and services for the oil & gas, petrochemical, and energy industries, ensuring safety, regulatory adherence, and long-term operational performance.

- ↗ Valves

- ↗ Reactors and Columns

- ↗ Instrumentation Valves

- ↗ Corrosion Monitoring System

- ↗ Branch Fittings (Olets and Flangeolets)

- ↗ Orifice Plates, Orifice flange

- ↗ CPVC Fittings, valves, strainers

- ↗ Axial Control Valve. Axial HIPPS,

- ↗ Isolation and Choke Valves

- ↗ Isolation Kits, Gaskets, Studs & Bolts

- ↗ Pipes, Fittings & Flanges

- ↗ Strainers

- ↗ Heat Exchangers / Pressure Vessels

- ↗ Expansion Joints / Bellows

- ↗ Potable Water Valves and pumps

- ↗ Spectacle blinds and Spades

- ↗ Chemical Injection System

Personal Protective Equipment & Safety Systems

Our company delivers industrial-grade safety equipment and personal protective equipment (PPE) solutions engineered to meet the rigorous demands of oil & gas, power generation, manufacturing, construction, and heavy industrial operations. We supply certified safety products designed to protect personnel in high-risk and hazardous environments while ensuring operational continuity and regulatory compliance.

All PPE and safety accessories are sourced in accordance with recognized international standards including ANSI, EN, OSHA, and ISO, ensuring consistent quality, performance, and workforce protection. Our product range covers head, eye, face, hand, respiratory, hearing, and fall protection systems, as well as specialized protective equipment for extreme conditions and high-exposure work sites.

Through reliable supply chains, technical product support, and strict quality assurance, we provide complete safety solutions that reduce workplace risk, enhance safety performance, and support compliance with industrial HSE requirements.

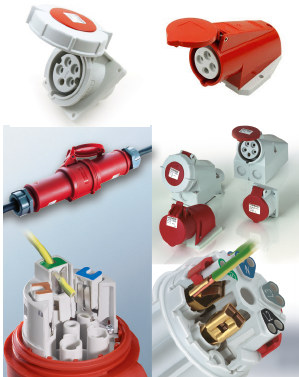

Electrical & Control Systems Engineering Capabilities

Our company delivers advanced electrical and instrumentation solutions focused on motor control, energy optimization, automation, and high-performance drive systems for industrial and infrastructure applications. We specialize in low voltage motors, variable speed drives (VFDs), modular drive panels, and fully engineered electrical systems designed to enhance operational efficiency, reliability, and lifecycle performance.

Our portfolio includes industrial drive systems ranging from fractional kilowatt to multi-megawatt capacities across multiple voltage classes, supporting critical applications such as pumps, fans, blowers, compressors, and HVAC. These systems feature modular architectures, regenerative and multi-pulse configurations, integrated safety functions, and advanced diagnostics for optimized operation and reduced maintenance.

We provide complete instrumentation solutions including field sensors, transmitters, control panels, and signal integration for process monitoring and control. Our automation capabilities cover PLC-based control systems, SCADA platforms, HMI interfaces, and networked industrial communications, enabling real-time data acquisition, system supervision, and intelligent energy management.

All solutions are delivered as turnkey engineered systems — from design and programming to installation, testing, and commissioning — ensuring seamless integration with existing plant infrastructure while achieving measurable energy savings, process stability, and operational reliability.

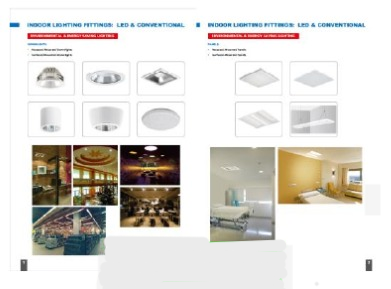

Advanced Lighting Systems & Engineering Solutions

We deliver engineered lighting solutions across residential, commercial, industrial, infrastructure, and sports applications, specializing in LED and conventional systems designed for energy efficiency, durability, and optimal illumination performance.

Our portfolio includes indoor downlights and panel systems (recessed and surface-mounted), industrial-grade luminaires for harsh operating environments, and complete outdoor lighting solutions such as street lighting, floodlighting, amenity, and security lighting. We also design and supply high-performance sports field and arena lighting systems compliant with international illumination standards.

We provide full street lighting infrastructure, including decorative poles and advanced high mast systems (fixed, hinged, raising and lowering), along with solar lighting, emergency lighting (maintained and central battery systems), and specialized hazardous-area luminaires including explosion-proof, vandal-proof, and weather-resistant designs. To ensure precision and efficiency, we integrate lighting controls, automation systems, and professional illumination modeling and rendered designs—delivering optimized light distribution, reduced energy consumption, and long-term operational reliability.

DEMAND MORE

DEMAND TERAWELL

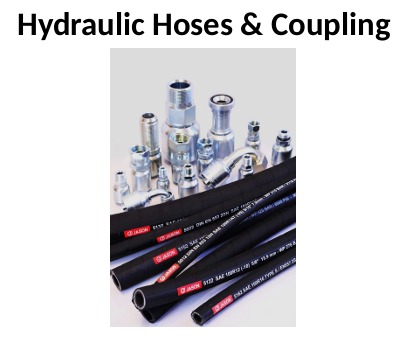

In the toughest of conditions, oil rig operatives need parts that won't let them down, from a supplier that won't let them down. One that will not fail under pressure.

They need a provider like Us: because when our customers demand more, we deliver – every time. With unsurpassed quality, in industry-leading lead times.

RECEIVE UNPARALLELED QUALITY

We prioritise quality and safety above all else. Our supplied products undergo rigorous on-site testing to ensure uncompromising quality, providing you with the peace of mind you deserve.

With the understanding that failure is not an option in demanding, high-performance applications, our Manufacturers' API (American Petroleum Institute) - certified products are designed to meet these needs continuously, day and night.

Trust in our legacy to deliver excellence in performance and safety.

RECEIVE UNMATCHED SPEED

We understand that quality alone is not enough; prompt delivery is crucial. That is why our commitment to innovative technology is at the centre of everything we do: our cutting-edge retroactive bonding (RAB) and state-of-the-art crimp technologies allow us to shorten lead times considerably.

Increase your uptime and productivity with standard delivery times that are faster than our competitors. Products delivered at the right time, every time.

RECEIVE UNCOMPROMISING RELIABILITY

In the realm of onshore oil rig operations, where demands are high, it's reassuring to have a nearby supplier that can precisely meet your needs when you need it most.

Our Manufacturer's strong global presence is rooted in a regional approach that allows you to benefit from the proximity of production and service facilities worldwide.

You can rely on a close-by parts provider without compromising on expertise, which remains unmatched in the industry.

From low-pressure to ultra-high pressure hose assemblies, and from application-specific systems to versatile fluid compatibility, the most productive hose systems start with the safest, most durable and efficient industrial hoses, couplings, accessories and equipment from us. Our Manufacturer is Recognised to meet over 20 international standards and quality certifications, Gates furnishes custom hose assemblies

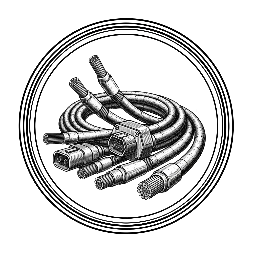

About our Partner Cable Plant

Our Partners specializes in the production of ESP Cable. The plant is a world-class production complex with a fully automated manufacturing process in compliance with top quality standards. The company has implemented the global quality management system ISO 9001:2015 and INTI S.QS 7-2024. The quality of manufactured products is a top priority for the company. The main goal is zero failures due to cable line defects.

Advantages

- Multi-stage selection of suppliers

- Strict acceptance tests: not only DC, but also AC testing of each drum is required

- A special formula for production of ethylene propylene rubbers (EPDM) with the highest dielectric resistance

- Quality inspection of 100% of surfaces using AI to identify defects

- Cable production tailored to the customer's specific requirements

CELF CABLE

(Cuprum EPDM Lead Flat)

CELF Cable is the industry standard of reliability and durability. This cable is the premium quality product of OFC plant. It's guarantees to operators ZERO failures because of cable. CELF cables enable to use ESP systems in the most difficult downhole conditions.

OFC CELF (Cuprum EPDM Lead Flat) cable is applicable in a wide range of temperatures from -40°F (-40°C) to 450°F (232°C). CELF cable is the best choice for extreme downhole conditions, featuring a special EPDM rubber insulation for high dielectric strength and excellent decompression resistance. A high modulus jacket and armor made of galvanized or stainless steel or Monel alloy provide the final layer of protection.

Capillary Tube

- Standard dimensions: 3/8" x 0.049" (9.525mm x 1.25mm)

- Material: Stainless Steel AISI 316L

- Splice dimensions: 13.9mm x 47mm

- Splice max pressure, up to 6000PSI (420 Bar)

CTTF CABLE

(Cuprum Cable Double Thermoplastic Flat)

The CTTF cable is made from polypropylene copolymers. It's designed by the company's engineers to help operators to maximize Production in a wide range of challenging downhole conditions. This type of material ensures that dielectric properties are maintained when the temperature rating is exceeded. OFC power cable designs have become the industry standard for reliability and durability.

OFC CTTF (Cuprum Cable Double Thermoplastic Flat) cable is applicable in a range of temperatures from -40°F (-40°C) to 266°F (130°C). CTTF cable is one of the most cost effective cables in the TPOE cable family. The high dielectric electrical grade thermoplastic insulation is formulated for down-hole applications. Another layer of electrical grade thermoplastic is applied over the insulation as a jacket that adds physical protection. This cable can be used in shallow wells, marginal oil wells and water well applications where large quantities of CO2, and/or light ends are not an issue. An armor made of galvanized or stainless steel or Monel alloy provides a high level of protection.

CTHT CABLE

(Cuprum Thermoplastic High Temperature)

The CTHT cable is made from polypropylene copolymers. It is designed by the company's engineers to help operators ensure reliable ESP operation under standard downhole conditions. This type of material ensures that dielectric properties are maintained when the temperature rating is exceeded. OFC power cable designs have become the industry standard for reliability and durability.

CTHT (Cuprum Thermoplastic High Temperature) cable manufactured by OFC is applicable in the temperature range from -40°F (-40°C) to 266°F (130°C). CTHT cable is economical and reliable. The insulation is made of especially selected thermoplastic with high dielectric parameters, resistant to copper ions. This type of cable can be used in wells whose fluid contains a large amount of carbon dioxide. CTHT cable is designed for operation in moderate well conditions. An armor made of galvanized or stainless steel or Monel alloy provides a high level of protection.

Overview

The health and safety of employees, clients, surrounding neighborhoods, and the larger environment are of the utmost importance to Terawells

Our health, safety, and environment standards are in alignment with our goal of being among the safest and most environmentally responsible companies in the world.

We are also careful to meet or exceed any additional health, safety, and environmental specifications requested by our clients.

Terawells prioritizes training our employees to meet the most rigorous standards of quality control while upholding health, safety, and environmental protections. We maintain active guidelines for implementing our HSE policies, all of which follow industry regulations and local and international law. We continually promote the safest possible work methodologies so that we may maximize the value we provide clients while protecting employees, local populations, air, land, and water.

Our company objectives are simple and easy to understand. They include:

- Maintaining the highest standards of quality control in our services & products while ensuring that they meet the technical requirements and operating specifications required by each customer’s unique field / environment.

- Upholding risk management protocols such that our personnel and operating environment are never in danger of injury, contamination, or other damages.

- Continually improving the quality of our products, services, and operational practices.

- Conducting frequent consultations with personnel and industry leaders regarding best practices in safety, health, quality, and environmental protection.

-

Quality

-

Safety,

Health &

Environment

Build Your Future with Us

We are a growing leader in the oil & gas and industrial services sector in Yemen, delivering high-performance solutions across energy, infrastructure, and operations. Our success is driven by talented professionals who bring expertise, dedication, and innovation to every project.

We offer a dynamic work environment with opportunities across oilfield operations, engineering, technical services, project support, and corporate functions. Whether in the field or in the office, our team members are empowered to develop their skills, grow their careers, and contribute to impactful projects that shape the energy industry.

Join us to be part of a team committed to safety, excellence, and long-term professional growth.

Get in Touch

If you've got questions or ideas you would like to share, send a message. For anything more specific, please use one of the addresses listed below.

For More information Contact Us

+967-775975001

Algeria Street

Seyoun - Hadhramout

Republic of Yemen